Work on Wolverhampton record-beater turns up a 200mph screwdriver

A major restoration campaign which aims to relive the finest hour of a world-beating Wolverhampton mechanical marvel has turned up an unexpected discovery – the first screwdriver to travel at 200mph.

Nearly 100 years ago a butterfingered Wolverhampton mechanic dropped his wooden-handled screwdriver into the innards while checking the oil level of the groundbreaking Sunbeam 1000hp car.

It joined the ride when, on March 29, 1927, Sir Henry Segrave drove the car into the history books by setting a new land speed record of 203mph at Daytona Beach, Florida.

National Motor Museum senior engineer Ian Stanfield said: “It’s the first 200mph screwdriver, which couldn’t have been taken out of the oil tank because it was buried under the engine. We cleaned out the tank where the oil had solidified, using hot water and detergent, and after shaking the tank the vintage screwdriver eventually tipped out.”

The National Motor Museum at Beaulieu and Hampshire-based Brookspeed Automotive have teamed up in the restoration project which aims to get the magical motor's V12 aero engines to run again and hopes to take the car back to Daytona Beach in Florida in 2027 to mark the 100th anniversary of its record-breaking feat.

It is hoped to take it for a historic run on the centenary date which will capture the imagination of people around the world.

Museum engineers want to recapture the sounds, sights, and smells of the machine and help to preserve it for future generations in a restoration campaign with a £300,000 fundraising target.

And as the work unfolds on the Sunbeam, which was affectionately nicknamed The Slug, various "time capsule" discoveries have been made.

A 1921 shilling was found in solidified oil on top of the rear spring suspension, and an adjustable spanner from the time of the landmark run was uncovered, similarly "glued" to the chassis by oil.

Ian said: “After the record-breaking run, the oil would have stuck like glue on top of the chassis which is where we made the other discoveries. It is like a time capsule which is all part of the incredible history of the Sunbeam 1000hp. It has only ever been driven for 50 miles to break the world record and these are the style of tools which would have been used by the mechanics when they built it.”

Soda blasting of the chassis, a specialist technique to remove loose paint, dirt and rust which is less aggressive than shotblasting, has exposed original markings which would have been applied at the Sunbeam Works in Wolverhampton in 1927.

Cracktesting revealed a crack in the engine subframe which has been ground out and rewelded by workshop engineers.

“We have not encountered anything we were not expecting to come across and considering how complex this project is, we are very pleased with what we have found,” said Ian.

The latest phase is seeing the three-speed gearbox being sympathetically cleaned and restored. The unique gearbox was created to turn the rear wheels because Sunbeam’s designer Captain Jack Irving was concerned about running such an immense amount of power through a conventional rear axle. It used drive chains, which glowed red hot during original testing at the Wolverhampton works.

An appeal by the museum for help in identifying people involved in the 1920s project has met with success.

"We have received a lot of feedback from the families of Wolverhampton workers at the Sunbeam works," said Jane Riddiford of the museum.

Donations for the Sunbeam 1000hp Restoration Campaign can be made online at https://nationalmotormuseum.org.uk/sunbeam-1000hp-restoration-campaign/ and sponsors and corporate donors who would like to be associated with it are being urged to get in touch with the museum’s development team.

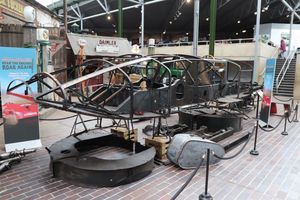

As the work continues, visitors to Beaulieu are able to see the exposed chassis on show in the museum.