Investment helps Alloy Wire win orders

Significant investment in a custom-built production line is helping a leading wire manufacturer to win new orders.

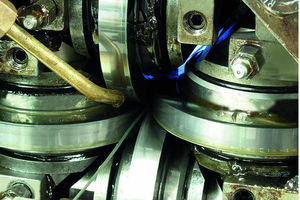

Alloy Wire International, which employs 28 people across its two factories in Brierley Hill and Yorkshire, has spent more than £150,000 on a host of new machinery that gives its customers access to wider and thinner or bigger cross-section profiles of up to 100 square millimetres in more than 60 different alloys.

The decision comes after a major customer research exercise and is already proving a successful decision, with more than £125,000 of new orders secured for the increased range.

"We are continually talking to our clients and finding out what would make their lives easier," explained Angus Hogarth, sales director at AWI.

"One of the main points they kept coming back on was being able to buy flat and shaped profiles in a wider variety of sizes, especially in bigger profiles. We listened and decided to commission a bespoke machine that could deliver just that and we're already seeing significant orders placed that we would not have won before."

"Customers also like the fact they can order in small quantities (starting from 10 metres) and that delivery is within four weeks to any part of the world."

Alloy Wire International makes round, flat, shaped profile and electrical resistance wires in a range of material that is growing by the month, with more than 60 currently available to choose from.

Mr Hogarth said: "Quality is crucial to everything we do and our technical and inspection departments ensure our clients receive the very best product. In order to keep up with enquiries from the aerospace and defence sector, we have also secured the AS9100 'aerospace and defence' accreditation.

"Our profiles are used for aircraft engine retaining rings to architectural grills, whilst some of our spring making customers use our wider flat wire for stamping out parts."